Liquibox S-Series

Liquibox S-Series:

Semi-automatic

bag-in-box filler

I understand that this information will be used to address my inquiry and to receive updates from Liquibox.

Fast, easy to operate, and reliable filling machine that grows with your business

We know what it is like to start small. That’s why we created an affordable and user-friendly line of fillers that empower your business to thrive at any stage. The S-Series is ready to evolve with you, whether you want to increase the output or simply change the packaging size.

Specifications

Standard features

The semi-automatic S-Series filler is equipped with:

- Light curtain for fully guarded design

- Convenient Clean-in-Place (CIP)

- One button fill height adjustment for operator’s convenience

- Magnetic flow meter

Additional Options

- Shear type fill valve for particulates

- Chlorine flush for sanitizing fill valve

- Turbine or Coriolis flow meter

- Nitrogen and vacuum capable for oxygen sensitive products

- Casters

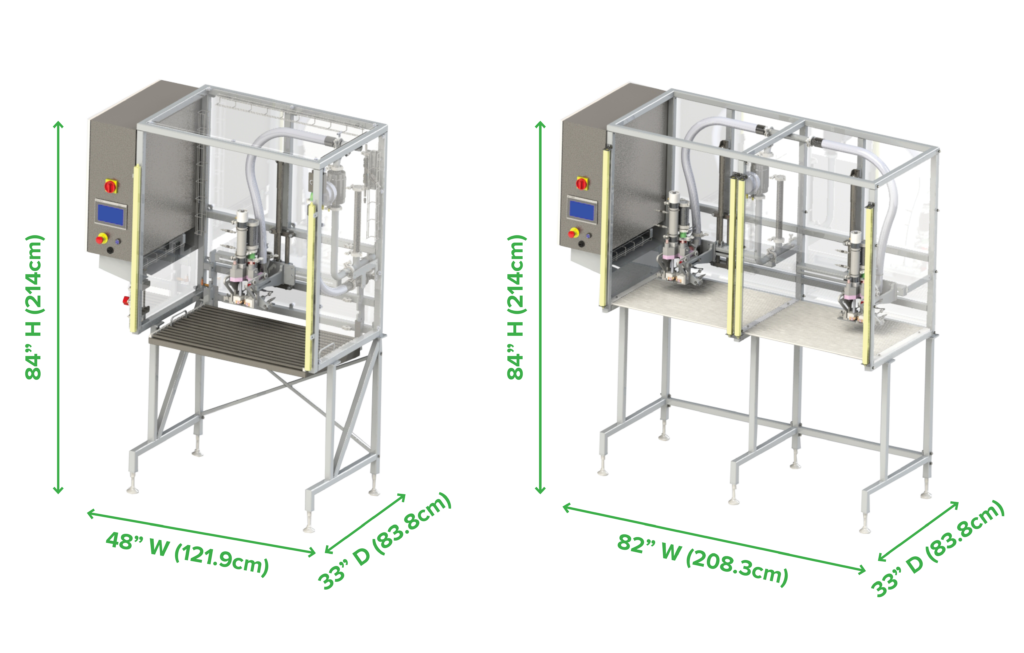

Dimensions

Single head:

33” D x 48” W x 84” H (83.8cm D x 121.9cm W x 214cm H)

Dual head:

33” D x 82” W x 84” H (83.8cm D x 208.3cm W x 214cm H)

Dimensions are subject to change based on options, conveyor height, and box height.

Industries

Beverage

Wine, water, post-mix syrup, juice, among others.

Liquid food

Dairy & dairy alternatives, eggs, edible oil, condiments & sauces, among others.

Non-food

Personal care liquids, automotive liquids, cleaning and home care liquids, paint, coatings & varnishes, among others.

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.

Filler sales and support: + 1-888-472-3400