Liquibox Intasept®

Liquibox Intasept: Aseptic bag-in-box filling systems

The Liquibox Intasept series features semi-automatic filling equipment for a wide range of high and low-acid products. Unlike other aseptic filling machines in the market, the unique patented Intasept aseptic filling technology offers the security of heat-sealed closure both before and after filling. The Intasept system is designed to fill 1.5-20L (0.5-5G) flexible bags for bag-in-box as well as bulk 210-1500L (55-395G) bags for drums, bins and intermediate bulk containers (IBC).

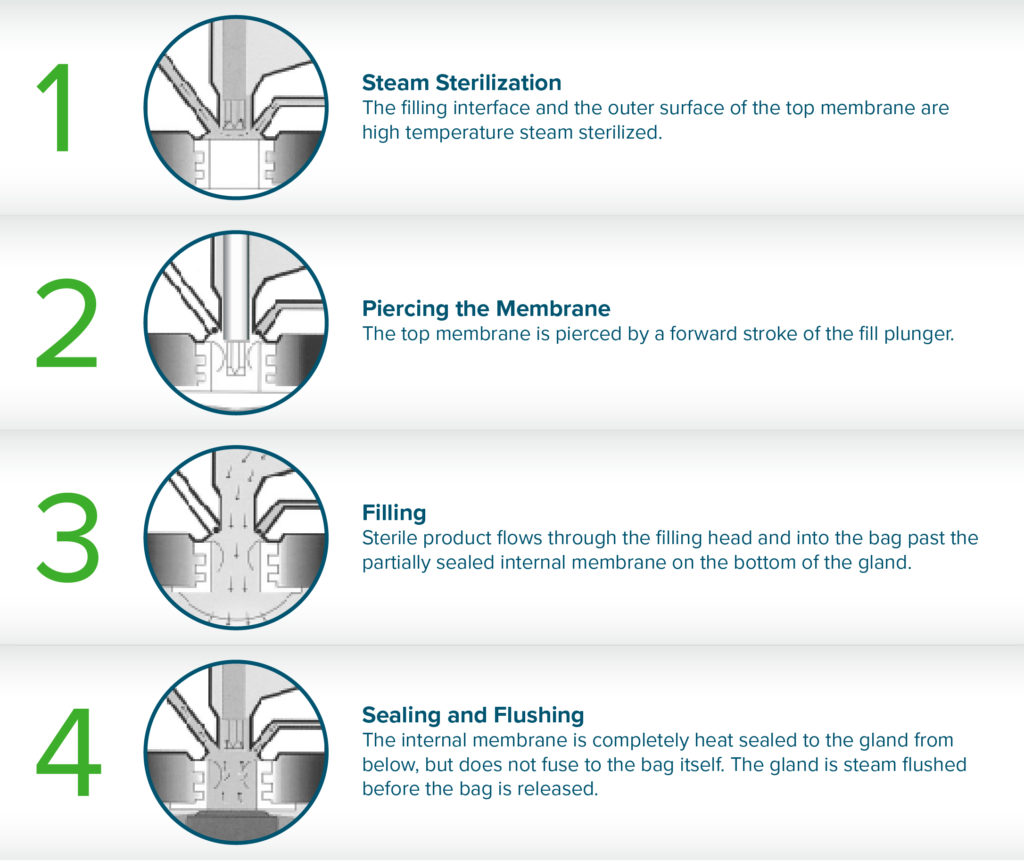

Intasept technology

The system is comprised of two parts:

- Double membrane: 16 or 32mm glands, available in round or rectangular shapes, guarantee heat-sealed closure before and after filling. Intasept system utilizes a patented energy riser technology for more effective and quicker reseal.

- Filler: ensures the sterile transfer for both low and high acid products without the use of chemical agents.

Benefits of Intasept filling machines:

- Easy operator interface

- Easy to install system with only steam, compressed air and single phase power

- No special factory environment is required as the closed transfer system excludes ambient air from all stages of the filling process

- Quick and simple bag size changes

- Cleaned in place/steamed in place features (CIP/SIP)

- Compact size

Our range of Intasept fillers

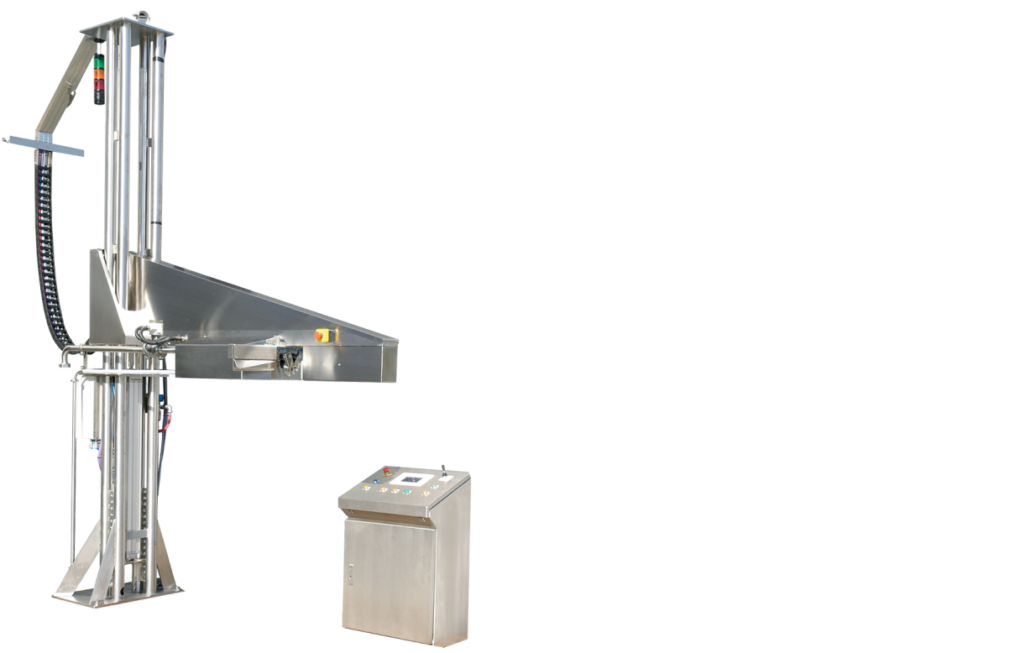

S-Series Intasept: single head or dual head semi-automatic filler

The Liquibox S-Series is an affordable and user-friendly bag-in-box filler that empowers businesses to thrive at any stage of development. The Intasept S-Series is designed to work with 16 and 32mm glands. Tap and piecer fittings are available for the 16mm gland.

Filling rate*

| Volume L (G) | Single head BPM | Dual head BPM |

| 4L (1G) | 4 | 7 |

| 10L (2.5G) | 4 | 7 |

| 20L (5G) | 3 | 6 |

Intasept 2800: single head bulk filler

A bulk filler designed to fill bags ranging from 5 to 1500L (1.5-395G). Ideal for filling fresh, stable and viscous liquid products.

Filling rate*

| Volume L (G) | Bags per hour |

| 5L (1.5G) | 140 |

| 10L (2.5G) | 140 |

| 20L (5G) | 140 |

| 210L (55G) | 50 |

| 1000L (265G) | 15 |

*The fill rate numbers are averages recorded in various client facilities. Actual rate is dependent on operator dexterity, product supply rate, and bag size.

Industries

Intasept aseptic filling technology is suitable for liquid and particulate products, both high and low-acid:

Beverages

Dairy, juices, coffee & tea, water, among others.

Food

Ice cream mix, coconut milk, creams, custards, soups, broths, sauces, fruit & vegetables purees, and pulp with particles up to 10mm

Ingredients

Omega 3, vitamins, enzymes

Bio-medical

Clinical feeding and cell culture media

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.

Filler sales and support: + 1-888-472-3400