Pharmaceuticals

At Liquibox, we believe in protecting the products that protect people. Flexible packaging is a convenient and sustainable solution for keeping non-invasive pharmaceutical liquids safe and sterile for controlled use at laboratories and medical facilities as well as for inter-hospital transit. Liquibox’s patented Intasept® aseptic transfer technology with double membrane filling ensures sterility for the most sensitive products—whether you are packaging bulk pharmaceuticals in intermediate bulk containers (IBC) for institutional healthcare use, producing oral and eye care products or working with chemicals and solutions for biological testing.

Flexible bag-in-box and pouch packaging’s closed-loop systems reduce the risk of cross contamination while extending product shelf life and minimizing product waste and environmental impact.

Bag-in-box

Bags & films for pharmaceuticals

Our single-use durable bags for pharmaceutical and medical products deliver superior oxygen and moisture barrier, drop protection, flex crack resistance and long-distance shipping durability. Our high barrier film technologies are designed to protect your product against UV light and provide excellent chemical resistance, including metPET with PE, Liquipure ultra and a specially-formulated, ultra-clean additive-free PE laminated film for all non-invasive liquids.

Our bags provide maximum product protection and over 99% product evacuation.

Liquibox offers a wide range of standard bag sizes from 1L (0.25G) to 1400L (370G) as well as customizable options. Our closed system flexible bags help to prevent unwanted contact with active ingredients which keeps users safe.

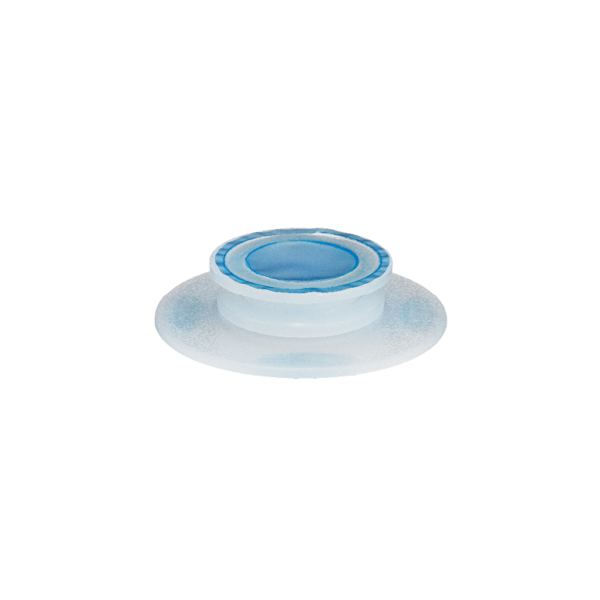

Fitments for pharmaceuticals

Our single-use aseptic fitments allow for secure and hygienic non-invasive product transfer and user-friendly dispensing.

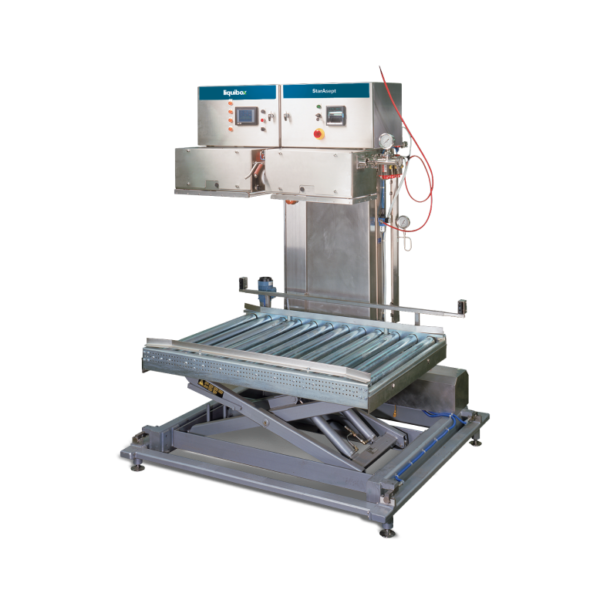

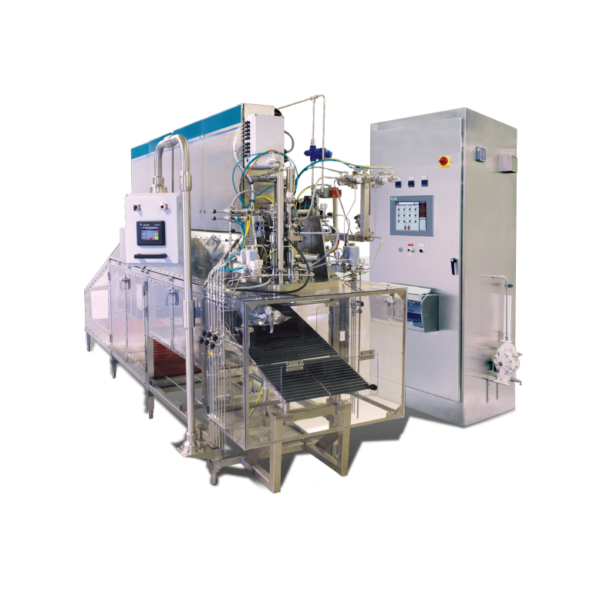

Bag-in-box filling equipment for pharmaceuticals

Our range of aseptic bag-in-box filling machines offer reliable, cost-effective and high-productivity filling to the medical industry. These compact fillers deliver superior product protection with their steam sterilization or chemical sterilant capabilities. The unique Intasept® filler technology is ideal for the pharma sector with its security of heat-sealed closure both before and after filling.

Why choose flexible packaging for pharmaceuticals?

Bag-in-box flexible packaging is designed to reduce product waste, improve efficiency in dispensing and preserve the quality of your sensitive liquids.

Learn more about the advantages of flexible packaging on our benefits page.

Related pages

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.