Dairy & Dairy Alternatives

Preserve freshness and protect your dairy products, from farm to fridge

For more than 50 years, Liquibox has led the way in creating innovative packaging for dairy and liquid egg products. From milk and milk alternatives to creamer, ice cream mix, yogurt, cheese and liquid eggs, we deliver standard and aseptic flexible bag-in-box and pouch packaging solutions that fit any and all of dairy needs. Our aseptic packaging systems mean your dairy products stay fresh and flavorful for longer and also reduce your need for a chilled supply chain.

You will find our flexible solutions across the globe in food service and commercial coffee and milk dispensing machines as well as in retail, inter-company transit, new product development and product trials.

Bag-in-box

I understand that this information will be used to address my inquiry and to receive updates from Liquibox.

Bags & films for dairy products

Our durable film structures for dairy products deliver outstanding drop protection, flex crack resistance and long-distance shipping durability. Our wide range of film technologies include Liquipure lite bags for fresh products, Liquipure ultra bags for ESL and UHT products and metPET with PE laminate for ultimate UHT protection.

With our Liquipure® lite film, enjoy superior performance coupled with a more environmentally responsible 20% film gauge reduction, while maintaining improved durability.

Liquibox offers a wide range of standard bag sizes from 1L (0.25G) to 1400L (370G) as well as customizable options. We also offer optional irradiation for enhanced product safety.

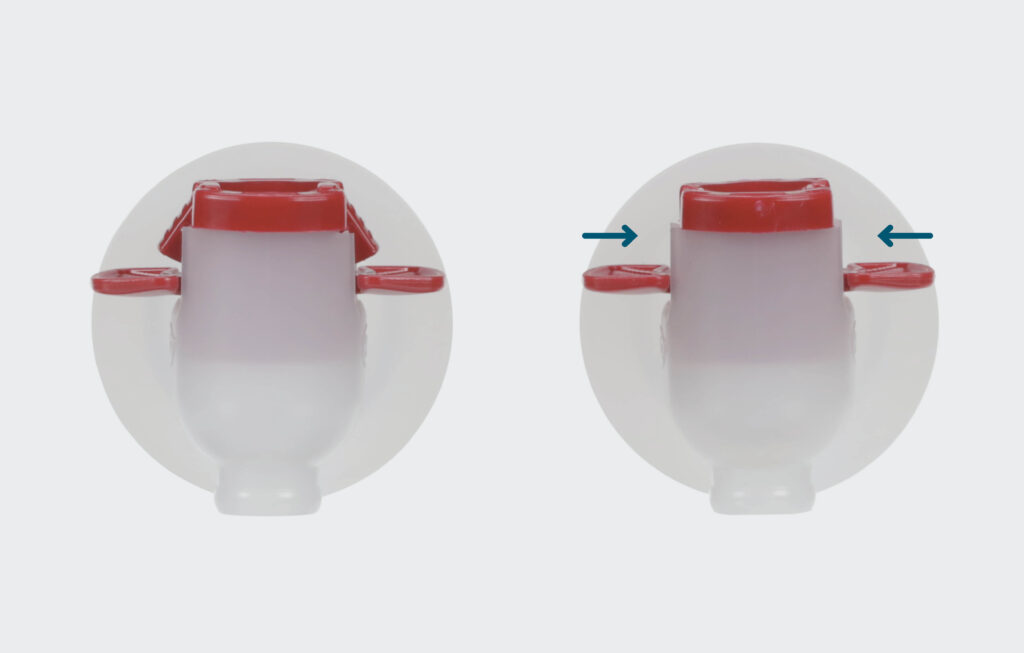

Fitments & dispensing taps for dairy products

We offer a wide range of fitments for the dairy industry including a variety of flat caps, tube caps, flip caps and pouring caps that easily and conveniently work with commercial dairy dispensing machines. We also offer dispensing taps with aseptic-capable versions available for smaller size boxed milk products that provide excellent oxygen barrier and optimized directional flow for convenient, single-handed dispensing by the consumer.

See our range of bag fitments on our Fitments page.

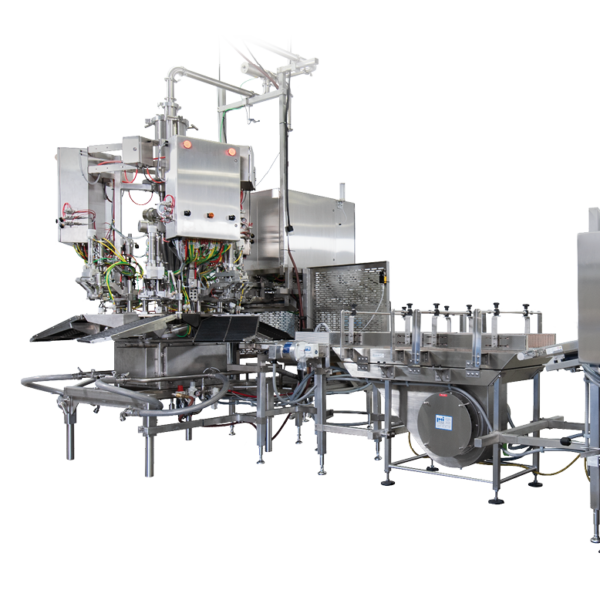

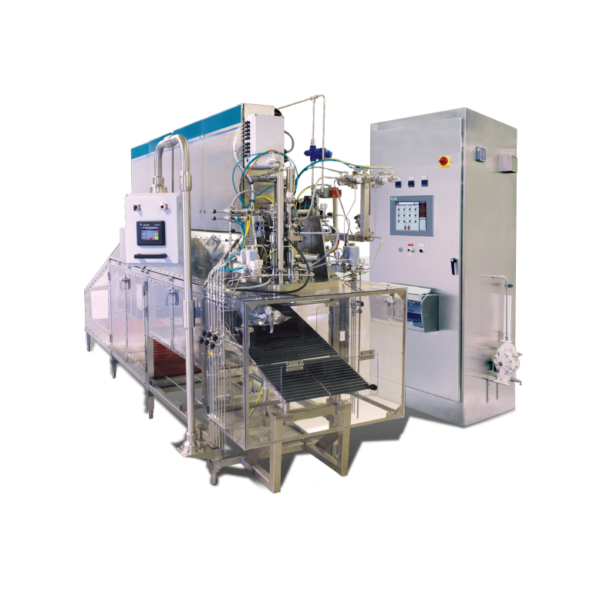

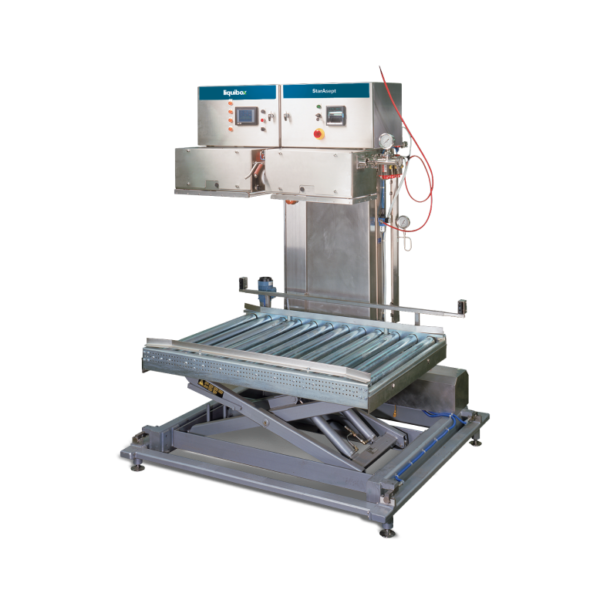

Filling equipment for dairy products

Our bag-in-box filling machines offer reliable, cost-effective and high-productivity filling to the dairy and liquid egg industry. We also offer a wide range of aseptic fillers with steam sterilization or chemical sterilant capabilities, delivering superior product protection. These compact fillers have the ability to adapt to a large range of dispensing fitments and bag size changes quickly and easily.

Why choose flexible packaging for dairy and dairy alternatives?

Bag-in-box and pouch flexible packaging is designed to reduce product waste, improve efficiency in dispensing and preserve the freshness and taste of your liquids.

Learn more about the advantages of flexible packaging on our benefits page.

Related pages

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.