Juice

Deliver great tasting juice products that stay fresh for longer

At Liquibox, we provide flexible packaging that preserves the quality and freshness of your juice products so consumers can enjoy the pure deliciousness in every sip. Our durable bag-in-box and pouch packaging for fruit and vegetable juice, concentrates, nectars and flavored fruit drinks is used in food service and institutional commercial dispensing machines as well as in retail globally. With our aseptic packaging systems, you can have shelf-stable juice that stays fresh for even longer and guarantees optimum flavor, color and appearance.

Bag-in-box

I understand that this information will be used to address my inquiry and to receive updates from Liquibox.

Bags & films for juice

Our durable film structures for juice deliver outstanding oxygen barrier, drop protection, flex crack resistance and long-distance shipping durability. We offer a wide range of barrier film technologies to protect your beverage, including Liquipure ultra, metPET with PE laminate, biaxially-oriented nylon (BON) laminated structures and a monolayer nylon EVOH laminate, specially designed for hot fill juice.

New! We now offer our award-winning recycle-ready Liquipure® ultra flexible packaging for juice, along with e-commerce packaging solutions.

Liquibox offers a wide range of standard bag sizes from 1L (0.25G) to 1400L (370G) as well as customizable options.

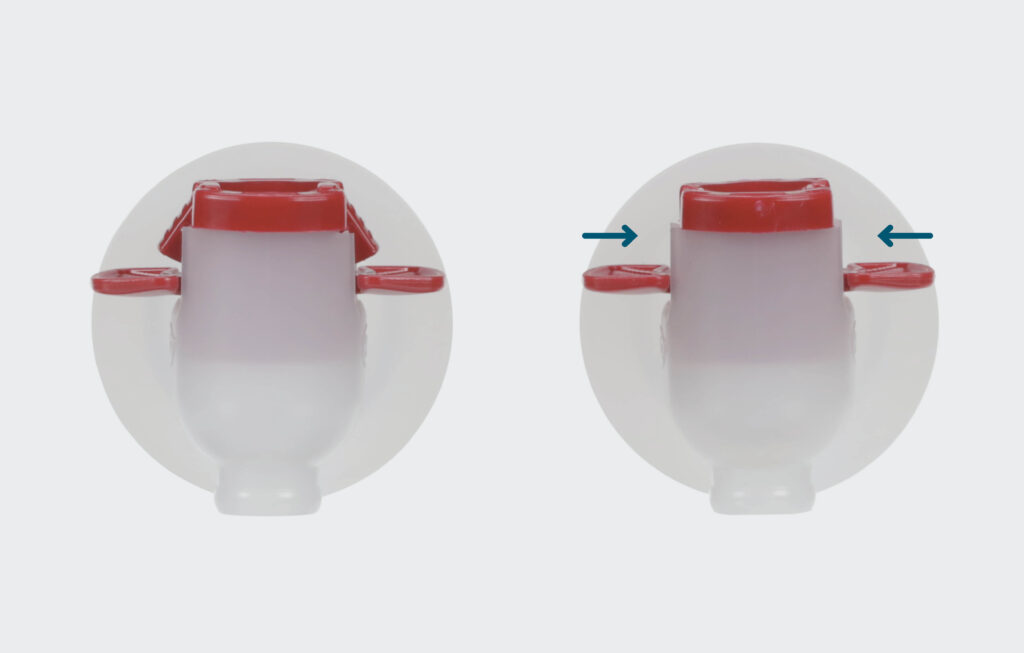

Line-side connectors, fitments & dispensing taps for juice

Our universal fitments and connectors easily and conveniently connect directly to commercial dispensing machines, ensuring precise and controlled mixes of beverages with minimal leaks or spills. We also offer dispensing taps with aseptic-capable versions available for retail boxed juice that provide excellent oxygen barrier and optimized directional flow for convenient, single-handed dispensing by the consumer. We also have offerings for handling juice with and without pulp or particulate.

See our range of complementary bag fitments on our fitments page.

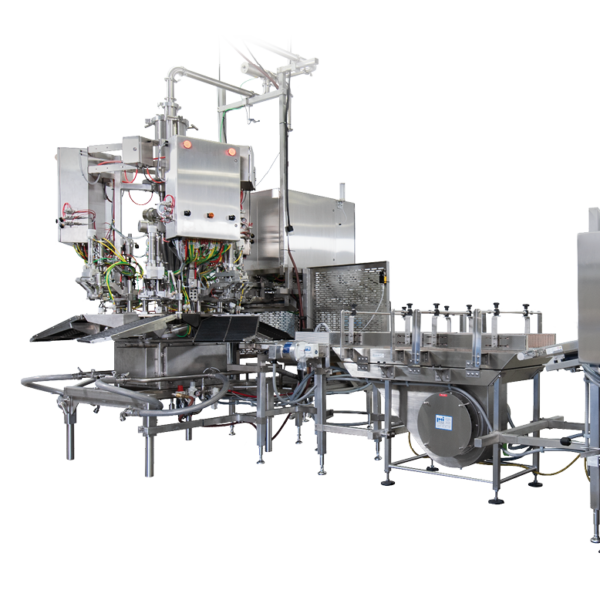

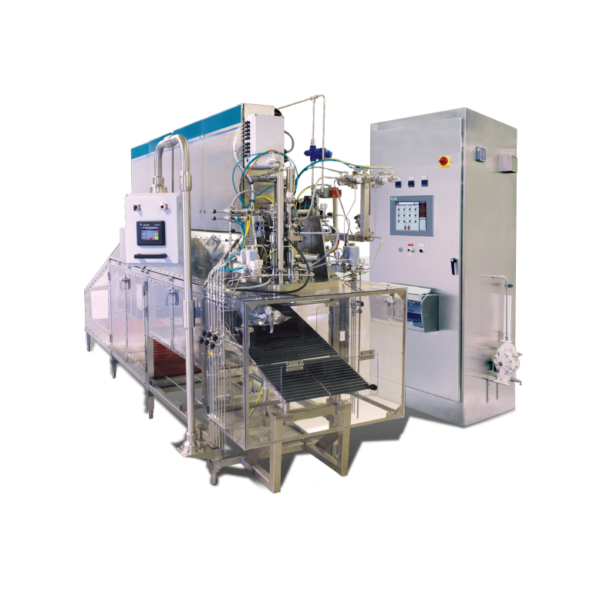

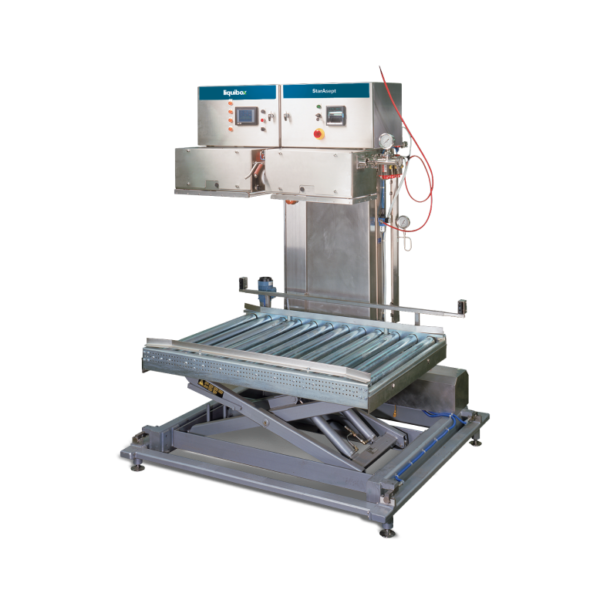

Filling equipment for juice

Our bag-in-box filling machines offer reliable, cost-effective and high-productivity filling to the beverage industry. We also offer a wide range of aseptic fillers with steam sterilization or chemical sterilant capabilities, delivering superior product protection. These compact fillers have the ability to adapt to a large range of dispensing fitments and bag size changes quickly and easily.

Why choose flexible packaging for juice?

Bag-in-box and pouch flexible packaging is designed to reduce product waste, improve efficiency in dispensing and preserve the freshness and taste of your beverage.

Learn more about the advantages of flexible packaging on our benefits page.

Related pages

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.