Smoothies

Protect your fresh ingredients so consumers can enjoy the natural goodness in every cup

As consumers move away from sugary beverages and look for healthy alternatives, Liquibox is committed to delivering durable packaging that keeps nourishing smoothie products fresh and safe. From yogurt and fruit-based smoothie mix to fruit flavorings, protein beverages and slushy drinks, flexible bag-in-box and pouch packaging keep your products optimal for even longer, guaranteeing freshness and consistent flavor, color and appearance. Our bag-in-box packaging is used around the world by the food service industry in commercial blended ice dispensing machines and cold beverage dispensers. Standard, pasteurized, aseptic and ESL packaging and filling options are available.

Bag-in-box

Bags & films for smoothies

Our durable film structures for smoothie products deliver outstanding drop protection, flex crack resistance and long-distance shipping durability. Our film technologies offer low oxygen permeability and protect the taste and quality of light-sensitive liquids such as dairy-based smoothies. Our wide range of film technologies include metPET with PE as well as Liquipure ultra and Liquipure lite.

With our Patent-pending Liquipure lite film, enjoy superior performance coupled with a more environmentally responsible 20% film gauge reduction, while maintaining improved durability for your dairy-based smoothies.

Liquibox offers a wide range of standard bag sizes from 1L (0.25G) to 1400L (370G) as well as customizable options. We also offer optional irradiation for enhanced product safety.

Fitments & dispensing taps for smoothies

Our smoothie taps and fitments are designed to easily and conveniently work with commercial dispensing systems and include pour-from options as well as fitments and connectors with a pump-out style system.

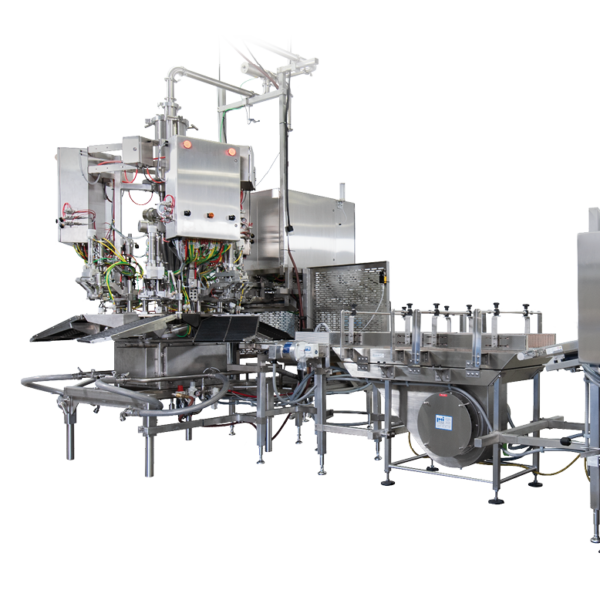

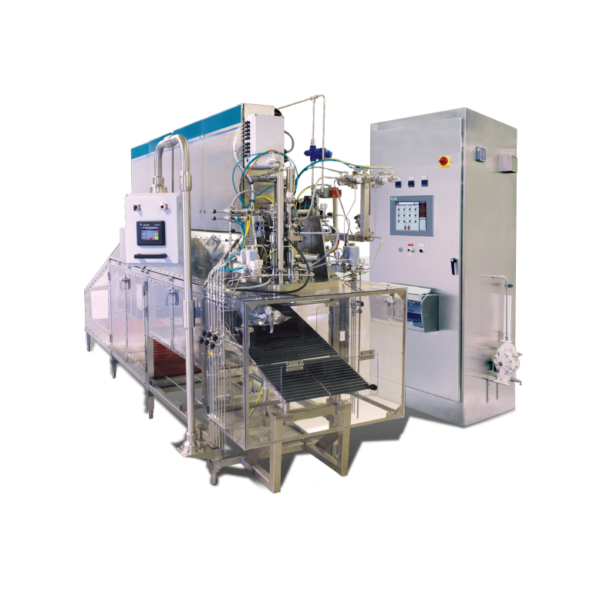

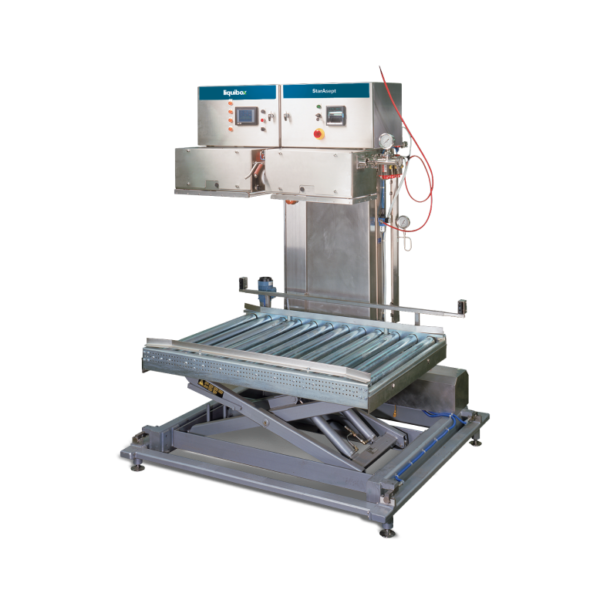

Filling equipment for smoothies

Our bag-in-box filling machines offer reliable, cost-effective and high-productivity filling to the liquid food and beverage industry. We also offer a wide range of aseptic fillers with steam sterilization or chemical sterilant capabilities, delivering superior product protection. These compact fillers have the ability to adapt to a large range of dispensing fitments and bag size changes quickly and easily.

Why choose flexible packaging for smoothies?

Bag-in-box and pouch flexible packaging is designed to reduce product waste, improve efficiency in dispensing and preserve the freshness and taste of your liquids.

Learn more about the advantages of flexible packaging on our benefits page.

Related pages

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.